Home / Blog / Domain Analytics / Applications of AI in Manufacturing Processes

Applications of AI in Manufacturing Processes

Table of Content

The Rise of AI

Artificial intelligence, or AI, is one of the concepts that has exploded in popularity in recent years, due to Hollywood sci-fi films and the digital age. Every day, the population grows, and with it, so do their needs. To meet the needs and maximise their profits, businesses and manufacturers are working nonstop, but this is insufficient. The cost of employees and manufacturing procedures are rising along with the demand. To cut expenses in this case, the manufacturing or production process must be optimised. In this field, machine learning principles and AI systems are becoming incredibly popular.

Creating a synthetic intellect with ingrained reasoning and decision-making abilities is what artificial intelligence, or AI, primarily entails. It also refers to a system that can automatically reason and make judgements without any form of outside human interference.

Right today, most systems and procedures in the digital era have been automated in order to provide services more effectively. Since most automated systems require data to function, data has emerged as the new contemporary fuel. Most businesses and organisations wanting to remain ahead of the competition now use data analysis and data science as a strategic weapon.

The majority of large-scale companies currently use AI systems in their production process, making the application of AI systems in commercial manufacturing processes quite frequent. AI technologies absolutely remove human mistake since they are automated and entirely digital. In comparison to their human counterparts, the output is also far faster and more exact. Also, AI systems are increasingly preferred over traditional industrial processes since maintenance costs are less than labour expenses.

Source:Google

Applications in the Manufacturing Processes

So, we have seen that AI systems are finding many opportunities in the manufacturing processes in various industries. They are being incorporated for a wide range of applications. Listed below are some of the major applications of AI in the manufacturing process. Click here to learn Data Analytics in Bangalore

Click here to Learn Data Science Training in Chennai

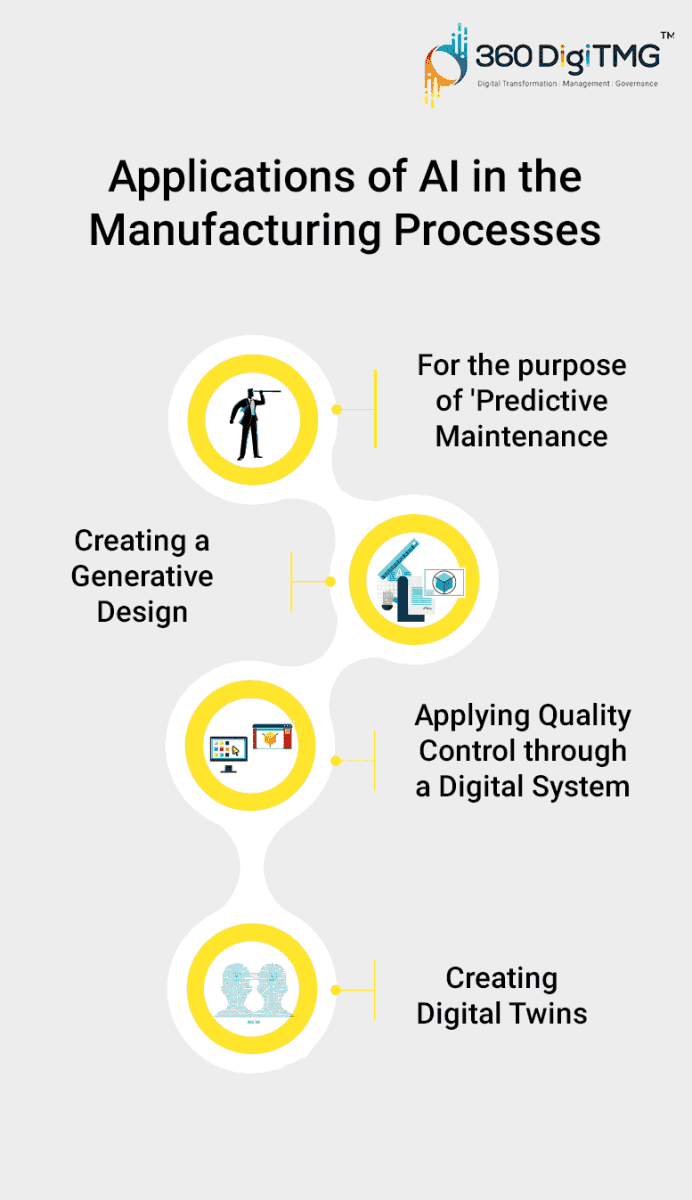

- For the Purpose of 'Predictive Maintenance-

We are all aware that large-scale manufacturing systems and equipment need routine maintenance. With time, the maintenance procedure has changed. Reactive maintenance was the norm in the past, which meant that when a piece of machinery broke down, it was fixed. The idea of periodic maintenance was created with the expansion of technological understanding. In order to avoid any serious faults in the future, the machinery got routine weekly or monthly maintenance services. We may utilise the programme to foresee future problems and avoid them altogether now that we have the weapon of AI at our disposal.

The data on asset utilisation may be sent into an AI system, which can perform certain calculations and provide us the precise limit and time of machine failure, as the majority of systems nowadays are automated. We may use this information to plan ahead and carry out maintenance in order to maintain the production process. In order to maximise asset life and identify precisely which machine components need maintenance, predictive maintenance is preferable to reactive and periodic maintenance. This makes it more economically efficient because no additional money has to be spent on fixing parts that are in great working order.

- Creating a Generative Design- The most important part of a manufacturing process is choosing the design of the product and the production technique. Choosing a product design is critical because there are various factors which are needed to be taken into consideration while initiating a production process. These factors include deadlines, raw material constraints, quality constraints, budget and others like these. All these factors and constraints can be fed into an AI system that can implement an algorithm to generate the most suitable solution. Click here to learn Artificial Intelligence in Bangalore This allows us to consider the maximum number of probable solutions before choosing the most suitable one. We can also program the maximum and minimum limits of the finished products to get the results within the specified limit. It must be remembered that the solutions obtained are only proposed solutions. Machine learning techniques can be applied to further refine the models and finally achieve the desired product design. This process is often termed as creating a generative design. The process can be repeated as many times as we like in a little time so the room of error reduces considerably, and it enhances the productivity of the whole manufacturing process exponentially.

- Applying Quality Control through a Digital System-

'Quality control' is the cornerstone of a production process. Quality control is crucial for every manufacturing process because without some sort of quality control system, the entire production process will be for nothing since the consumers will reject the end product. Even the best expert's judgement contains some human mistake, therefore decisions can never be completely unbiased. In general, certain experts are recruited for quality control measures.

AI has aided by offering a workable solution to this issue. Computer visions may be trained to watch over even the smallest aspects of a production process to guarantee that the final product is completely error-free. Additionally, computer vision can always detect any small inaccuracy that is frequently overlooked by the human sight. Computer visions are much more accurate than human eyes and are capable of spotting even the smallest differences between layers or patterns. Additionally, the AI system may be given measurements of the final product to guarantee the output's exact proportions, which is typically not something a person can achieve. The AI system may be taught the production process data so that it can recognise the flaws in the manufacturing process itself.

- Creating Digital Twins- We are living in the age of increasing competition and rapidly declining resources. Every large scale company or firm has to be very cautious before setting up a manufacturing process because any kind of mistake in the production process can lead to massive losses both in the terms of money and resources. Sometimes even the greatest of plans can get foiled due to some unforeseen circumstances. Click here to learn Machine Learning in Hyderabad But what if we could prevent this from happening at all? That's where the concept of digital twins comes in. The concept of digital twins refers to the creation of a model of the proposed production design, which will work in real-time according to the real world constraints applied to it, thereby giving us an idea of how the actual manufacturing process will turn out in the real world. We can use this feature to identify any kind of error before going into actual production. This can also be used to run tests of experimental scenarios to check the conditions which can maximize the productivity of the process. The information or data which we obtain from digital twins can be used to improve the production process and also create enhanced and better manufacturing processes.

Will this Continue to be Popular?

definitely, Yes.

The manufacturing process is the most important phase of the production cycle in all industrial sectors, and businesses are always looking for methods to optimise it. It goes without saying that AI has provided these businesses with a wide variety of previously unattainable choices. We have noticed a significant improvement in the completed goods as a result of the deployment of AI systems, despite the fact that this stage of their use in the production process is still in its infancy.

Artificial intelligence has already made a significant impact in the quality of the completed goods and improved the production process considerably. The idea of using AI in manufacturing has been quite popular as a result of this. The majority of big businesses spend a lot of money on hiring data scientists to create AI systems for their manufacturing processes.

One thing is clear from the facts provided above: artificial intelligence has fundamentally altered how we used to carry out our industrial operations. We now have more accuracy and more effective control over the final product's quality. We are able to successfully alter the product's restrictions and the many conditions that must be met for it to function.

As a result of how much faster AI has made decision-making and quality-control procedures in manufacturing, more and more businesses are searching for ways to use AI systems. It must be remembered that the idea of artificial intelligence and machine learning is still in its very early stages and will only become better with time. Future advancements will lead to an exponential rise in demand for AI techniques, and eventually the entire manufacturing process will be AI-controlled. Therefore, it is safe to assume that the use of AI in industrial processes is a growing trend and will continue for some time.

Data Science Placement Success Story

Data Science Training Institutes in Other Locations

Data Analyst Courses in Other Locations

Navigate to Address

360DigiTMG - Data Science, Data Scientist Course Training in Bangalore

No 23, 2nd Floor, 9th Main Rd, 22nd Cross Rd, 7th Sector, HSR Layout, Bengaluru, Karnataka 560102

1800-212-654-321